Project: 1969

Chevrolet Chevelle

SS

Status: Completed

Here are some details about the 1969 Chevrolet Chevelle SS:

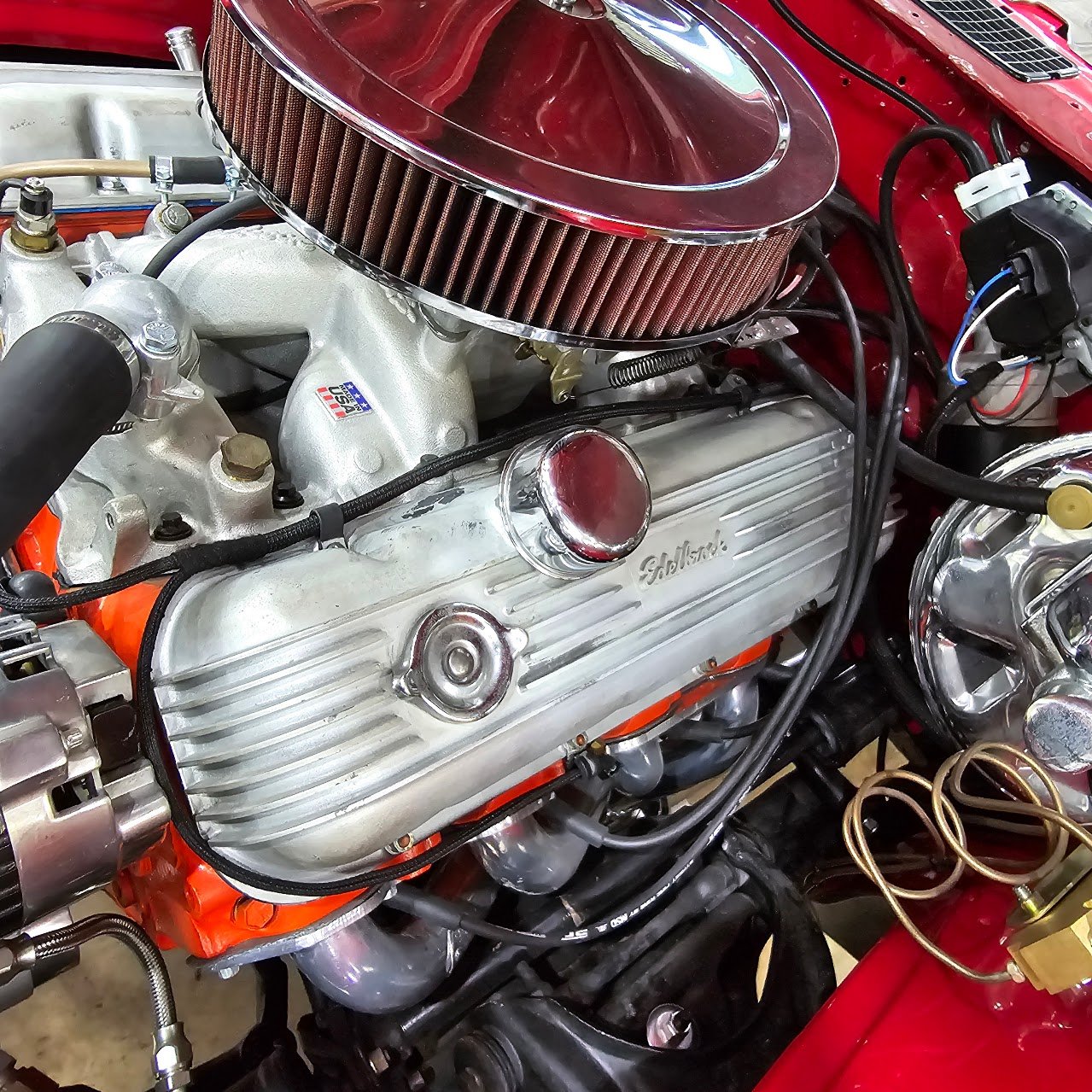

Engine:

The base model was equipped with a 396 cubic inch V8 engine that produced 375 horsepower at 5600 rpm and 415 pound-feet of torque at 3600 rpm. It featured a 1 x 4 bbl fuel system and had a compression ratio of 11.0:1.

Performance:

The 1969 Chevelle SS could accelerate from 0 to 60 miles per hour in 6.5 seconds and complete a quarter mile in 14.5 seconds at a speed of 101 miles per hour.

Transmission:

The Chevelle SS offered seven transmission options, including two manual three-speeds, two manual four-speeds, an overdrive three-speed, and two automatics.

Body Styles:

The Chevelle SS was available in hardtop, convertible, and post-coupe body styles.

Safety Features:

The 1969 Chevelle SS included new safety features such as a collapsible steering column as a standard feature.

Options:

Optional features for the Chevelle SS included Superlift air shock absorbers, Strato-ease headrests, and full instrumentation.

Wheelbase:

The wheelbase measured 112 inches for two-door and convertible models, and 116 inches for all other models.

Dimensions:

The Chevelle SS was 76 inches wide, with heights ranging from 52.7 inches for the convertible to 54.3 inches for the station wagon.

History

and Facts

PROGRESSION PICS

The Final stretch

Mechanical Labor

Paint & Body

with Andrew

-

Body removed frome frame

Chasis sanded down

Primed Chasis for paint

Painted Chasis

-

Prepared underside of body for Raptor lining

Lite sanding and a wipe down with degreaser

Sprayed Raptor (x2)

-

Mounted body back to the Frame

-

Finished the custom box for the Subwoofer

Adjusted kick panels for speakers

Made custom panels for the trunk to mount the amp

Ran power cable from engine bay back to the trunk to provide power to the Amp

Cable management & looming

Fabrication

& Mechanical Labor

with Tyler

-

sanded speedo gear to get proper clearance

installed speedo cable bullet and gear into transmission

installed speedo cable at transmission and ensured minimal issues with shifter linkage

ran speedo cable up through firewall and installed it's gromet

added pedal pads and polished old pad trims to match the new ones

installed clutch rod boot

unpacked new glass and window track kit

looked into what needed to be modified and what didn't

made a list of materials needed

-

finished creating horizontal cross bar for glass

test fitted bar and dropped glass in place.

Hooked up cross bar and tested window movement.

partially removed driver's inner fender

ran front ebrake cable through floor and hooked up to pedal

mocked up cable routing

reinstalled bolts for inner fender

mocked up front cable mount

drilled and nutcerted cross member for E-brake mount

cut cable

installed mount

hooked up cable

adjusted E-brake cable

-

marked steel bar where cutting was needed and deburred

cut custom glass insulators

cut old window mounted brackets

made new ones to mimick original style for a 69 Chevelle

welded sliding bracket together

welded rear fixed bracket together

installed cross track

snugged all ends

test slid into passenger door track with great success

started modifying other parts of window tracks to create the horizontal cross bar

-

prepped body for windshield install

prepped windshield for install

installed windshield with not great success

removed glass and cleaned body up of excess urethane

removed urethane from glass to prep for second attempt at install the nfollowing day

-

cleaned windshield of all primer

reprepped glass for another install

installed windshield with success

installed windshield trim clips and trim

organized gauge wiring and repositioned speedometer cable

dropped steering column for gauge panel install

hooked up speedo cable to speedometer

hooked up wiring to gauges

installed gauge panel

remounted steering column

instaled under-column panel

found ideal location for console mounting

melted holes in carpet for cleaner install

drilled mounting holes

mounted center console and reinstalled top metal panel

-

Test ran the car with the key

found that carburetor electric choke was sticking

removed and disassembled choke

cleaned and lubricated choke

reinstalled and readjusted

test ran again

tested cutouts and found they didn't work

investigated cutout issue

resoldered a wire into its control board

unpacked radio and started installation

-

wired in radio

mounted radio

tested for radio power

revised some wiring for radio

tested cutouts again: found that there was insufficient power

ran power wire to fuze block (switched so key needs to be on)

tested cutouts and ran car

-

unpacked Convertable top rams and hydraulic pump

installed rams

installed pump in its place

double checked proper plumbing for hydraulic lines

installed lines

found electrical connector for pump

hooked up rear connector

ran wire extensions for Convertable top switch

-

found connectors for top switch and hooked up top switch

hooked up battery charger to make sure battery didn't die during top operation for bleeding

filled pump reservoir and ran system multiple times

tightened some adjuster bolts for Convertable top and retested

lubricated all top joints

-

installed blinker lever and tested blinkers for functionality

unboxed drivers side window tracks

drilled out spot welds on tracks

prepped larger track to be welded together

welded larger track together

staightened larger track and cut to length

mounted horizontal shaft to glass to ensure proper fit

-

cut steel to weld front sliding track to mount to glass

welded small sliding track and bolts to steel

made glass insulators

mounted front track to glass

cut rear track wheel off of kit

cut piece of steel to weld to it as a spacer/mount

drilled hole and welded bolt inside

welded wheel to mount

mounted rear wheel to glass

installed horizontal bar to power window track in door

adjusted rear vertical track

slid driver's door glass in place

mounted horizontal track to glass

tested functionality

removed old broken Convertable top tension springs and cables

installed new ones

adjusted rear side of Convertable top to get the arms straight to be able to adjust door glass on both sides

-

installed washer bottle and bracket

adjusted washer bottle lip to fit cap better

adjusted and installed battery hold down for Optima style battery

installed shifter ball

installed drivers side astro vent in dash

brought over passenger side door panel and test fitted

cut hole for inside door latch

found ideal location for door panel armrest to utilize original holes

located ideal spot for window switch

cut hole for window switch

mounted window switch

installed clips in door panel

measured for even screw hole locations for bottom of door

installed arm rest and all handles

installed licence plate light

-DRIVERS DOOR PANEL ↓

found ideal location for door panel armrest to utilize original holes

located ideal spot for window switch

cut hole for window switch

mounted window switch

installed clips in door panel

-

measured for even screw hole locations for the bottom of the door

installed armrest and all handles on the driver door

installed wiper arms with some modifications on the driver's side arm

adjusted the driver's side wiper arm

tested for functionality

cleared out the trunk and organized what parts were left to install that are here

hooked up rearward console courtesy light

tested door locks and found the switch was backward.

unpinned 4 wires on each side and pinned them in the proper order for correct functionality

-

installed rear glass with minor modification

preadjusted rear glass

encountered and found wiring issue with relay box causing a dead leg headed to the fuze block preventing some things in car to not have power

installed front right astro vent

started making center dash vent

-

Finished trimming center A/C vent

Glued a/c vent together

adjusted mount locations to clearance for screws

installed center A/C vent

-

installed hood louvers after some massaging of hood and louvers on passenger side

installed new ididit box

installed glovebox and lock

removed passenger side door panel and installed the respective outer window felt

-

adjusted passenger side door window to finished top

fixed a broken roller on front of window and replaced with more appropriate length one after modifications

new ididit ignition relay box blew a fuse internally

tacked wires and found that too many accessories was wired to the same leg on the relay box so the power windows are now on its own separate relay leg

added some major modifications to passenger rear window track to match up to the finished top and finally got it adjusted properly

wired in switches to rear windows nicely in center console so rear windows can be operated without getting out or moving as requested

modified and adjusted drivers side rear window tracks to close nicely to the finished top

marked proper locations for rear seat hold down brackets and are ready to be bonded

reinstalled door panel on passenger side door after that door is finished

hooked up center vents to A/C box

-

cleaned good trim and rear top trim

installed hood trim

trimmed holes, painted washers, and tightened bolts to inner fenders

adjusted drivers rear window

adjusted drivers door window

bonded rear seat brackets to floor

-

installed all remaining window felts

finished adjusting passenger side windows

Installed rear door panel

removed back of seat to install the rest of side panel that covers the convertible top

finish adjusted drivers side windows

Installed drivers side panels

installed rear seat and both window crank handles

found any remaining required or missing parts

installed front shocks

installed passenger front seat

fixed hood safety latch

installed new trunk weatherstrip

installed trunk floor plugs

installed windshield pillar weatherstripping

finished a multitude of other small things and adjustments that needed to be done

found that engine was incredibly out of tune. Removed vacuum advance, adjusted timing, adjusted idle mixture significantly, adjusted timing again, adjusted idle speed, reattached vacuum advance

-

checked transmission fluid level

adjusted alignment for test drive

test drove

adjusted idle mixture with vacuum gauge reference

checked plugs for color

test drove again

prepped header trim panels for fiberglass molding

installed visor brackets

installed rear view mirror

installed horns to front of car

restored steering wheel center cap and horn buttons

tested horn buttons on both sides

improved horn ground

made fiberglass header panel molds

trimmed molds to be read to make new panels

attached fabric convertible top "basket" to rear seat

swapped convertible top outer rear trim to a new set

adjusted clutch pedal throw

-

removed windshield trim and convertible top clamp plates

installed factory style vinyl sheet to header in prep for header panels

reinstalled windshield trim

used header panel molds to make new panels

fixed any defects from the molding process

bodied new header panels and are ready for primer, paint, then install.

-

made new windshield washer squirters to mimic factory style and installed

ran new washer pump lines

filled washer bottle, primed, and tested

-

fabricated new rear convertible frame covers

test drove at cruising speed and found that new driveshaft was bent and sent it over for it to get fixed via warrantee

installed finished fiberglass header panels

installed and adjusted visors after minor modifications

made remaining trunk floor plugs and installed

fixed lower plastic pieces on driver's seat so they tuck up where they need to be from the factory

-

installed trunk light

recieved new driveshaft and test drove

found that it still had a rough vibration at 50+mph

pulled driveshaft and inspected suspected unreplaced tailshaft bushing. Ordered new bushing and seal

-

removed exhaust, trans crossmember, shifter linkage, shifter, reverse light switch, speedo cable, and tailshaft from transmission

removed old tailshaft bushing

installed new tailshaft bushing and seal with flange sealer to minimize possibility of leaking

reinstalled tailshaft housing, exhaust, trans crossmember, shifter linkage, shifter, reverse light switch, speedo cable

test drove and driveshaft vibration is severely improved but vibrations are still coming from transmission

removed exhaust, trans crossmember, shifter linkage, shifter, reverse light switch, speedo cable, and transmission

disassembled transmission and found out that the input shaft bearings (outer and inner) wore down or not rolling smoothly as it should.

found proper replacement bearings

-

reassembled transmission with new bearings and resealed shifter fork cover, input shaft bearing retainer,midplate, and tailshaft

installed transmission back into car after cleaning the excess grease off of the throw out bearing

remounted crossmember, trans mount, shifter linkage, and reverse light switch

-

reinstalled exhaust system to headers

hooked up exhaust cutout wiring

added fresh gear oil to transmission

reinstalled driveshaft

hooked up speedo cable

adjusted clutch (further adjustment may be needed during test drive

Mechanical Labor

with Brian

-

Sandblasted flash rust on 2 wheels, sanded lips of 2 wheels with 180, wax & grease removed.

with Dylan

-

Ran power and ground cable for amp

Ran chassis ground

Started fabrication of subwoofer box

-

Mounted all 4 tires with Andrew by hand

with Bucky

-

Balanced all 4 wheels and tires

Began to wash the protective coating off the white letters with warm soapy water

Tyler ended up using his spray-on solution to whiten the letters

Paint & Body

with Jio

-

sanded glove box

masked glove box

set up glove box

mixed primer

sprayed primed on the glove box

-

blew off and wiped down with a dry rag to remove dust

wiped down the car with water

masked tail lights, Matt black trim and rear bumper

masked trunk jamb

masked both door jambs

masked hood jamb

masked hood louvers

masked head lights, grille, and front bumper

masked 4 marker lights

masked both door handels and lock cylinders

masked belt molding

masked and wrapped convertible top to protect from compound

-

buffed the vehicle twice with step one on the wool pad to get out a majority of the defects

went around and marked what needs to be addressed more aggressively with sanding

-

sanded a few spots with 800 grit to remove imperfections

sanded the 800 grit with 1200grit

sanded the 1200 with 2000 grit

buzzed the 2000 with 3000grit tract

buffed the 3000 with step one on a wool pad

bigger the right quarter panel, door, fender and half the hood with step one on The foam pad

-

Window Track Kit

1968-72 Windshield Molding Clips KMC-68KITA

1964-72 Chevelle Brake Pad IHQ-0191

1964-72 Clutch Pedal Pad IHQ0191

1968-72 Firewall Rod Boot SS-5053

1964-77 Chevelle Door Striker BPX-1299

1964-77 Chevelle Parking Brake Connector Cables EC-8001U

Transmission Driveshaft Yoke 80292425

License Plate Bracket AMD-W-309

Convertible Top Cylinder Cables AUP-CCT1011

Spicer U-Joint SDH-5-153X

Air Cleaner SUM-239433B

White Shifter Ball FZ-1420

Turn Signal Lever IT-5174

1969 Chevelle Convertible Top Switch Bezel MTB-17

1968 -72 Vinyl Header Molding HEADERM10

1968-72 Convertible Header Seal JSS-091

Window Track Kit

1968-1972 Chevelle Convertible Top Weatherstrip Kit JSS-5093

1968-1969 Chevelle Hood Louvers NL-100

1964-1969 Chevelle Windshield Washer Plastic Jar Mounting Bracket AWB-8939

1964-1977 Chevelle Windshield Washer Cap, Hose & Screen Kit APX-9738

1964-1972 Chevelle Stainless Steel Battery Tray Retainer ABR-9533-SS

1966-1972 Chevelle License Plate Lamp MEH-1576

1968-1972 Chevelle Rubber Stopper Kit JSK-82K

1968-1972 Chevelle Front Arm Rest Pad And Base Kit Black ARM-KIT4

1969-1972 Chevelle Bucket Seat Back Release Kit IFC-521K

1968-1970 Chevelle Tilt Steering Column Lever IT-5168

1968-1969 Chevelle Dash Vent Ball Retainer Bezel Right Side IDV-689R

1969 Chevelle Dash Vent Ball Retainer Bezel Left Side IDV-69L

1969 Chevelle Astro Ventilation Dash Emblem IK-0046

1969 Chevelle 2 Door Coupe Replacement Style Outer Window Felts Only CH243R

1968-1972 Chevelle Door Panel Adjustment Clip Rear IDP-14465

1967-1970 Chevelle Long Style Hazard Lamp Flasher Knob IFK-1

1969 Chevelle Door Jamb Vent JTE-5043

1964-1972 Chevelle Lower Rear Seat Retainer Kit IBX-99KR

1968-1972 Chevelle Cowl Vent Grilles With Air Conditioning N-4512

Chevelle Dash Center AC Vent Housing Assembly ICV-702

69 Chevelle conv quarter glass tracks/hardware CH28161-PR

Notes: https://www.opgi.com/window/glass/quarter-window-assembly/assembly-quarter-window-1968-69-chevelle-coupe-pair-ch28161-pr.html

FR ss 69 Chevelle wheel 15" WVI-50-5734438

Astro vent hose adapter 3" to 2.5" VTA-49870-VCI

70 to 69 Chevelle center air duct adapter VTA-62614VCE

Notes: One needed to make the 70 air duct splitter fit and work in the 69. Minimal modification is still required

69 Chevelle convertible header molding

CONVERTIBLE TOP SWITCH 69 CHEVELLE W-081

Notes: The old switch melted at the rocker end by spring internally causing the switch to not return. Presumably caused by bleeding the system

14" Air Filter

Pillar Post Seal

Door Jamb Seals

Trunk Seal

Floor Pan Drain Plug

OE Style Compete Horn Kit

1969 SS396 Grille Emblem

Front Shock

Horn Repair Kit

Spare Tire Anchoring Plate

Spare Tire Retainer