Project: 1972

El Camino

Status: In-Progress

History

and Facts

Here are some facts about the 1972 Chevrolet El Camino:

Engine

The 1972 El Camino had several engine options, including a 250-6 with 110 horsepower, a 307 V8, a 350-cubic-inch V8 with 175 horsepower, and big block V8s with 402 and 454 cubic-inch displacements.

Horsepower measurements were based on "net" figures, which were taken with all accessories and emission controls installed.

Weight

The full-framed muscle car weighed over 3,600 pounds, but the front end was made 90 pounds lighter, giving it a 54/46 front-to-rear weight ratio.

Body

The 1972 El Camino was the last year for the Coke-bottle-shaped Chevelle body, which had been introduced four years earlier.

The El Camino was closely related to the Chevelle, and many parts from the windshield forward were interchangeable between the two cars.

Production

57,000 El Caminos were produced in 1972, and they were mostly used as work trucks.

Options and accessories

Some options and accessories for the 1972 El Camino included air conditioning, SS stripes, chrome wheels, stereo systems, tachometers, and bed liners.

ESC

1972 Chevrolet El Camino

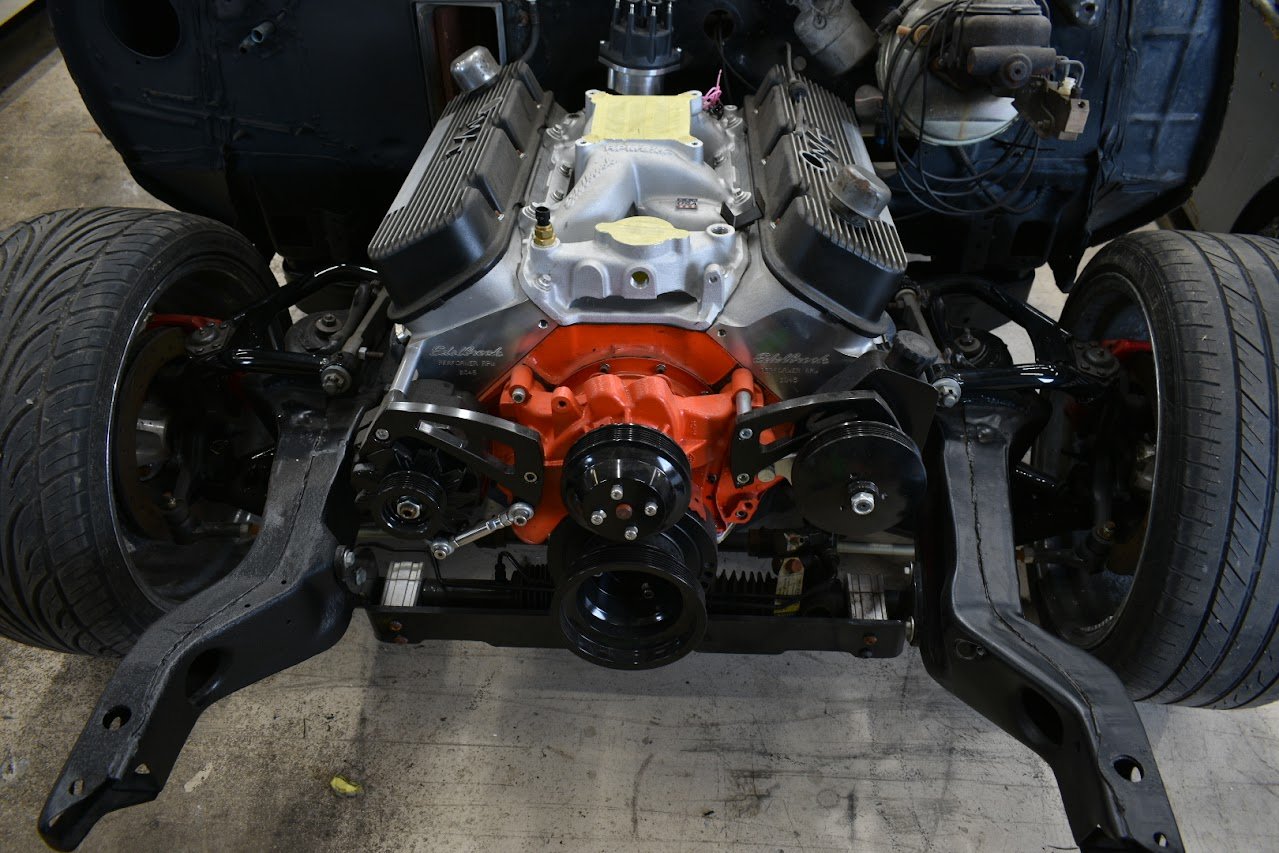

454 Big Block

Gear Star Performance 4L80

Hotchkis Suspension

American Autowire Classic Update Harness

Holley Performance Sniper 2 to be installed

Holley EFI Fuel Tank

Wilwood disc brakes

The chassis was repaired and repainted

The entire floor pan was replaced

We are just getting started on cutting out and replacing the rotted wheel tubs, we are replacing the driver-side quarter panel and repairing the outer rockers.

We will stretch the wheel tubs as far as we can without getting into chassis modifications to fit the biggest tire possible.

Fabrication

& Mechanical Labor

with Tyler

-

installed hubs back on spindles

reinstalled front calipers

reinstalled steering rack

organized new body mounts and placed them onto the frame in prep for the body to be dropped on

-

Instructed Barnes with wiring, while getting the new Wiring harness mocked up

Waiting for body to be mated to frame to continue wiring

-

Disassembled and refurbished engine. Parts, paint, accessories

Repainted block

Installed Engine mounts on frame

Mounted Engine to the frame

Made alterations to Trans crossmember in order for the transmission to sit properly

Painted crossmember

Placed Trans on trans mount

-

removed a large portion of old floor

trimmed away corners of old floor down to pinch weld

removed old floor supports

cut away small portion of rusted floor by drivers feet that wasn't able to be welded to and replaced

removed storage bucket and found more rust

replaced upper portion around storage bucket

mocked in new floor

welded in new floor supports

-

cut out passenger side wheel well with airsaw, cutoff wheel, drill, and weld breaker and started on driver's side

finished removing driver side wheel well

skinned drivers side of bed to prep for new panel

removed pinchwelded sections behind the rear tire and above the driver's side rocker panel

started adjusting and mocking new panel

Mechanical Labor

Bucky

Brian

-

Took the dashboard out and made labels for each wire

removed harness

helped Tyler install new harness and trim to fit

-

Removed hubs from spindles

Removed front calipers and suspension

Dropped out the Brake lines

Removed upper and lower control arms (L+R)

-

Removed the body mount bolts

double checked the frame & body for anything that could snag during the separation process

Lifted Body from frame

Made note of body mounts. Quantity, size, and condition

Suggested new Body mounts and bushings to be ordered

-

sand blasted rusty components

painted components

-

Prep frame for powder coating

use a grinder to smoothe out rough welds and ensure uniformity and that foreign contaminate is removed in prep for Tyler to weld

-

Installed new UMI Performance rear supports

-

Reinstalled brake lines as best as I could to the chasis and frame